Forest.Bot – Forest planting machine (Patent Pending).

Machine features:

Self-propelled;

- Intelligent, terrain-adaptive suspension;

- Autopilot to guide the machine over the forest fertilization line;

- Plant native or exotic species in installation areas, reform or recover degraded areas, regardless of soil dirtiness;

- Eucalyptus planting with irrigation and/or gel;

- Plant native species with or without irrigation and/or gel;

- Application of ant killer during planting;

- Registration of the seedling’s GPS position with a KML map of the planting;

- Photographic record of each seedling with verification of planting quality, with identification of seedling inclination, stem drowning, and substrate exposure;

- Sliding and continuous planting system with micro soil reading. The planting beak follows the irregularities of the terrain to always plant at the correct height;

- Electronic and mechanical analysis of soil and subsoil, identifying obstacles above ground or buried;

- Carousel for 30 seedlings (lines of 90 meters or more);

- Transports 6,000 seedlings in trays or boxes or more;

- Plant 1,800 seedlings per hour;

- Selection of planting spacing via software;

- Machine operation monitor and telemetry for driver and operator;

- Telemetry of all machine elements and components in real-time;

- Automatically informs of the need for preventive or corrective maintenance;

- Uses compressor roller to ensure uniform planting quality.

Our embedded technology allows the recording of this data in the cloud to present the planting map online, adding to the planting service the georeferencing control of the seedlings, thus resulting in cost optimization with real-time monitoring of planting success, in addition to enabling the automation of processes necessary for forest management.

From the moment you use the Forest.Bot (Patent Pending) for planting the forest, we will be able to automate processes, such as fertilization of the seedlings point by point, optical irrigation of the seedlings with a system to irrigate six simultaneous seedlings, combating pests around the tree, forest inventory, and analysis of the sanity of the forest, all this using the same mechanical and technological platform as our Forest.Bot (Patent Pending), through georeferencing and AI, to identify the seedlings.

Settings of Forest.Bot. (Patent Pending)

Meeting the customer’s expectations and peculiarities, the machine’s design will be configurable, showing the cost for the standard version with functionality exclusively aimed at planting and the values for each of the other features if required.

This customization of machine production allows, for example, to install only the autopilot system to drive the machine autonomously, among other methods.

It is worth noting that our expertise, backed by projects already developed and, in full effectiveness of the potential of our functionalities, enables us to present the innovation that represents the Forest.Bot version 9.0 release 3.0 (Patent Pending).

The development achieved with prototypes 1, 2, and 3 and other prototypes allowed the improvement that resulted in the successful development of version 9 with all the items mentioned above: self-propelled engine, automatic pilot, ant control and irrigation, seedlings, and planting of native or exotic species in areas of reform, installation or recovery of degraded areas.

Summarized features:

Plant with or without gel (seedlings);

- Autopilot;

- Apply formicide;

- Irrigate the seedlings;

- Maximum speed 3,600 seedlings/hour;

- Continuous operation.

Forest.Bot v.9.0 r.3.0. (Patent Pending)

Description:

Our company has focused on agribusiness challenges and sought technological solutions to ensure greater efficiency in planting and managing forests and nursery seedlings.

Our commitment to sustainability has always been the starting point of our projects, allowing each new version of our forest planting machine to add new features and improve what was already proving to be efficient.

As we looked into the challenges of agribusiness, we came across the reality of using a set of machinery with isolated functions, which, in addition to increasing planting costs, also increased the complexity of logistics.

Making the planting process an optimized flow was the guiding principle of our technological development.

The current Forest.Bot (Patent Pending) version 9.0 release 3.0 (forest planting machine) is the result of this continuous process of improvement and very efficiently replaces several agricultural implements, such as the planting team and quality control team, bringing in addition to considerable savings in planting forests, greater efficiency, more quality and speed in planting seedlings.

In a constantly evolving market scenario, the forest planting machine Forest.Bot version 9.0 release 3.0 (Patent Pending) is the cheapest and fastest solution for planting exotic and/or native species continuously, working up to 24 hours a day, with quick stops to receive new boxes or trays with seedlings.

The planting carousel moves up to 30 seedlings at a time, which ensures the planting of rows of 90 meters or more, and the feeding system for new seedlings in the carousel is manual. The machine transports more than 5,000 seedlings in boxes or trays at a time to ensure faster planting. Future versions will feature a robotic system for placing seedlings on the carousel. Still, due to the severe conditions faced in the planting reform areas, we opted to use the manual replacement of seedlings on the carousel in this version of the machine.

Forest.Bot versão 9.0 release 3.0 (Patent Pending)

The customization options for Forest.Bot v.9.0 r.3.0 standard (Patent Pending), with ant poison, planting with gel or point-to-point irrigation, seedling position recording, verification of the planting quality of each seedling and connection to the cloud system make silvicultural planting or of forests much faster, cheaper and with a higher rate. The machine is self-propelled and works with a pilot and an operator to dispense the seedlings.

Forest.Bot V9R3 S – Suspension, GPS, irrigation, ant killer, and A.I. (Patent Pending)

EQUIPMENT DEVELOPED FOR FAST, EFFICIENT, AND QUALITY PLANTING

KNOW THE BEST ATTRIBUTES OF OUR FOREST PLANTING MACHINE

Representing innovation in a highly competitive market, our Forest.Bot version 9.0 release 3.0 (Patent Pending) consolidates itself as the most economically attractive option with surprising functionality in plantation management.

Below is a brief description of all the solutions the forest planting machine offers.

POWER AND TECHNOLOGY

- Power from 130 to 190 horsepower in 4 different models.

- The new powers make it possible to irrigate and apply insecticide, regardless of the soil type and condition.

- Self-propelled for more efficient work with fewer agricultural implements.

- The new Bot (Patent Pending) can be done without a planting team and quality control; planting with gel can be done in the machine itself, and control optional, and water in the seedling during planting.

- The new Bot (Patent Pending) Dispenses with at least one tractor for irrigation and/or application of planting gel, a team for application of ant killer, a group for water application, accelerates planting with gel, eliminates quality control team, and reduces to one operator the planting of up to 25 (twenty-five) hectares per day per machine in periods of 20 hours per day.

- Lower consumption because it is a single piece of equipment dispenses with several others.

- Planting without interruption. Transshipping seedlings is a quick and straightforward process.

- Embedded technology: Agricultural engine with electronic injection; transmission option.

- It performs gears automatically, according to the load, and uses the hydrostatic transmission system with independent and intelligent suspension on each wheel in its complete V9R3 S version.

HST SYSTEM (hydrostatic transmission)

As Forest.Bot (Patent Pending) is equipped with HST and has an exclusive intelligent and independent suspension system per wheel in their complete version (V9R3 S). This innovative system allows the machine to be moved on any terrain, regardless of dirtiness, to ensure quality planting in renovation areas.

SINGULARITIES OF Forest.Bot (Patent Pending)

- The SPS (Sliding Planting System) exclusive of the Bot (Patent Pending) allows planting at any tractor speed, without the need for synchronization between the systems and allows planting in any soil, changing the planting speed automatically, presenting the following solutions:

- Dispenses seedlings automatically.

- Apply gel (optional).

- Apply water to each seedling (optional).

- Apply pesticide (optional).

- Checks planting quality. Collect sinking and seedling inclination.

- Records information on the quality of planting of each seedling in a database.

- Records the GPS position of each seedling.

- Create a basin for water accumulation.

- Interchangeable planting nozzle for quick maintenance in the field.

- The plant system copies soil irregularities to plant at the correct height.

- The planting system checks objects or obstacles to avoid planting over stumps, roots, trunks, stones, etc. The soil reading system comprises a set of electronic and mechanical systems to ensure greater robustness and efficiency.

NEW FOREST.BOT SERIES(Patent Pending) FORESTRY VERSION

AutoAgroMachines was the first company to present a reliable solution to achieve silvicultural or forest planting fast, efficiently, and with an exclusive intelligent system to verify the quality of the operation. With an option of 1.88 meters between axes, the machine quickly passes between planting rows or any minimum spacing of 3 meters without difficulty, removing any debris underneath that compromises planting.

The machines Forest.Bot (Patent Pending) can plant any nursery seedling of native, exotic, fruitful, or ornamental plants (eucalyptus, mahogany, pine, coffee, avocado, orange, lemon, MPB, among others). The machine presents functionality and efficiency for both forestry planting and reforestation. The spacing between seedlings is selected during planting and can vary according to the project’s needs, with adjustable intervals of 1 meter.

- Spacing between seedlings with selection via the system.

- Spacing between seedlings can be adjusted during planting in 1-meter increments, starting from a minimum of 2 meters, i.e., 2, 3, 4, 5, 6, 7 meters, and so on.

- The machine can transport the equivalent of 3.2 hectares of seedlings, considering 1,667 seedlings per hectare as standard.

From the platform of the standard version of Forest.Bot v9.0 r3.0 (Patent Pending) the AutoAgroMachines developed the following optional features:

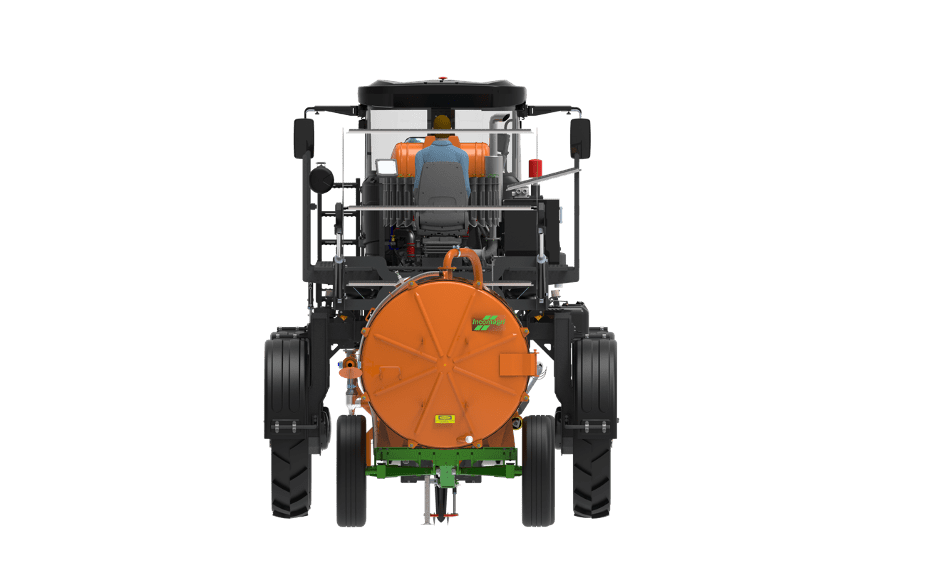

PLANTING WITH GEL AND WATER

The forest planting machine can be coupled to a water injection system with gel for safer planting in times of more significant water deficit. At the same time as planting, the machine prepares the “basin” to receive a calculated dose of water, which can vary from 500ml to 4 liters per seedling (selection via an embedded system), providing greater security for the plantings in times with little rainfall, working with the following operations in this customization:

- Optional planting with water and gel.

- Dispensing water from 500ml to 4 liters per optional change, with selection via the machine’s proprietary system.

- The machine can also optionally receive a quick coupling to couple the water dispensing system to a pipe, which the machine can pull.

- The previous calculation of the maneuvering area ensures that the machine’s handling is coupled to a kite.

OPTIONAL FORMICIDE

As Forest.Bot (Patent Pending) can receive a deposit of ant poison located just above the planting system (planting nozzle), which dispenses the programmed amount of ant poison right after planting the seedling. This system optimizes and anticipates fighting ants, usually carried out right after planting.

- Reservoir for 30 kg of ant killer.

- The ant-dispensing system can be programmed into the control unit of the bot (Patent Pending), establishing the moment when the ant killer will be released right after planting.

- Quick recharge system.

- Easy access reservoir.

SPS (SLIDING PLANTING SYSTEM)

The system SPS (Sliding Planting System) was developed exclusively by AutoAgroMachines for your Forest.Bot (Patent Pending).

In this functionality, our forest planting machine is equipped with an exclusive and innovative sliding planting system (Patent Pending), which guarantees shorter times in the complete planting cycle of each seedling. The sliding system (Patent Pending) also allows each seedling to be planted in its entire process in a time equal to or less than 1 second, enabling us to plant up to 3,600 seedlings per hour. This system works perfectly without requiring mechanical synchronization between the machine and planting speed. It can operate at speeds of up to 8 km/h in the following configuration according to the model shown below:

- Allows planting with variable spacing selected by the machine’s proprietary system.

- Reinforced module for planting approximately 42,000 seedlings/day.

- Planting spacing is adjustable via software directly on the machine console.

- Does not require synchronization with machine speed.

- Easy maintenance of the hydraulic system.

- Self-locking return-to-base system.

- Operates at speeds up to 8 km/h.

- Completes a planting cycle within 1 second.

- It can be configured through the central computer of the Bot (Patent Pending).

- It has a sliding axis of at least 3 meters.

- Make a basin to accumulate water.

- Press molt to remove air pockets around the seedling substrate.

- Check for obstacles when injecting the seedling into the soil.

- It records the GPS position of each seedling on a planting map that will be sent to the cloud.

- Level ground to brake.

- It has an innovative system for leveling and stabilizing the planting beak (Patent Pending).

- Check planting quality using A.I.

Innovative sliding planting system (Patent Pending)

SIS (SEEDLING INJECTION SYSTEM)

The system SIS was developed and tested by AutoAgroMachines for the last six years exclusively for the Forest.Bot (Patent Pending) ensures excellent quality and speed in planting tree seedlings (native or exotic).

The seedling injector system Forest.Bot (Patent Pending) guarantees clean, fast, efficient, and jam-free planting, having been specially developed for planting in times of rain. This prevents possible mechanism locks even when operating in more sticky soils.

The development stages of our machines indicated that the biggest problem faced by the user of other technologies in planting with a planting nozzle or planting wheel is precisely the mud, which renders the equipment inoperable. With that in mind, we created and approved this new innovative technology under natural conditions of use.

The innovative technology embedded in the Forest.Bot (Patent Pending) reads the undulations of the soil to ensure more incredible planting speed, keeping the injector nozzle close to the ground and increasing the system’s accuracy. In this context, the machine operates with the following functionalities:

- The machines Bot (Patent Pending) uses Industry 4.0 technology.

- By category, Bot (Patent Pending) of forest planting machines use IoT (Internet of Things) to interconnect all machine systems.

- Ultrasonic and mechanical reader to determine the distance from the injection nozzle to the ground.

- The ground clearance calibration system automatically keeps the injector 5cm from the ground.

- Self-blocking return system.

- The injector nozzle protection system prevents any object from obstructing planting.

- Positioning system with inertial velocity calculation to ensure that the GPS position of each seedling will be recorded correctly.

- Systembot uses an exclusive Neural Network (Artificial Intelligence) to identify the planting quality of each seedling, determining whether there was a sinking of the stem, exposure of the substrate, whether the seedling is inclined, and whether the seedling was planted or not.

- Our modern and exclusive planting quality verification system initially records all information on the machine’s computer. Identifying an authorized internet network automatically transfers all leads to the cloud to the AutoAgroMachines management system.

- Prevents the accumulation of mud in the planting system.

- Sliding system to follow the movement speed of the machine without requiring specific synchronization.

- Hydraulic systems for controlling the movements of the injection nozzle.

- The length of the sliding system is at least 3 meters.

- Self-cleaning system to prevent mud build-up.

- All components of the seedling injector nozzle were developed to guarantee excellent resistance and outstanding durability.

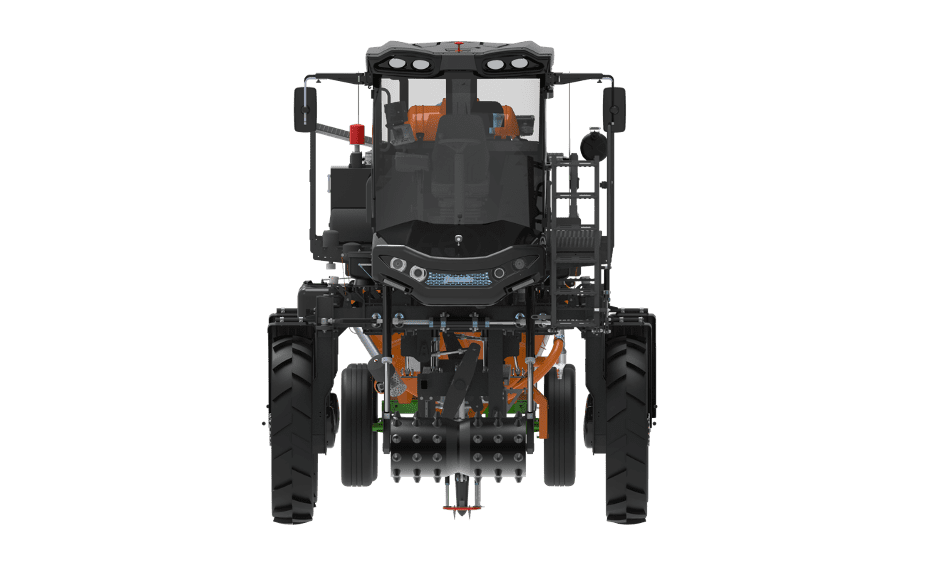

Rear view of the machine.

FOREST.BOT (Patent Pending) forestry RCCM

| AUTONOMY | BASE |

|---|---|

| Lines | One n |

| l | 3,2 m |

| E. plants (adjustable) | min. 2,8 m |

| Area/change | 8,96 m2 |

| ha | 10.000 m2 |

| The density of plants (variable) | 1,116 average e.plants/ha |

| Speed h | 4,00 km/h |

| Productivity | 1,800 to 3,600 seedlings/hour |

| Productivity (according to spacing) | average 1.6 ha/hour |

| Autonomy of Seedlings | 5,400 seedlings in the machine. |

| Max. Boxes in the machine | 14 trays with 200 seedlings |

| Autonomy of Seedlings | 3 hours of work |

| Autonoma Pipa | average 8,000 liters |

| Attached is a kite (not part of the machine) | Connected |

| Kite autonomy | 1.8 ha |

| Maximum stops for refueling | 8 stops |

| Tank capacity (diesel) | 390 liters |

| Water | 4 liters/change |

| Diesel | 15 liters/hour |

| Formicidal | 30 kg |

| Bait box capacity -> for | 25ha |

| hours | |

| Hours day | 24 |

| Turns | 3 |

| Snack | 3 |

| Others | 0,2 |

| Reach Diesel | 0,5 |

| Reach Mutas | 0.50 12 min, 2x a day |

| Supply Pipe | 1.50 6 min., 15x a day |

| Blanket preventive | 1 |

| Mant. Correct | 0,4 |

| hours | |

| TU (Usage Fee) | 70% 16,9 |

| DM (mechanical disposition) | 92,1% 22,1 |

| EO (operational efficiency) | 77% |

| HT (hours worked) | 514 |

| The useful life of Sulsolator/Fertilization | 5 years |

| Service life Engine, transmission, gearbox | 15 to 25 years |

| Planting system (beak) | 2.5 years |

| Estimated maintenance cost per hour worked | |

| Months of work for maintenance | 3 |

| Hours worked/day | 24 hours |

| Diesel consumption/hour | 15 liters |

| Embedded technology cost | |

| Systems (annual) | R$ 9.000,00 |

| Time required for filling | |

| Pipe | 6 minutes |

| Seedlings | 12 minutes |

| Formicidal | 5 minutes |

| Maximum load | 14 trays |

| Planting autonomy without recharging | 3.2 ha |

MACHINE INTEGRATED INTO THE CLOUD MANAGEMENT SYSTEM

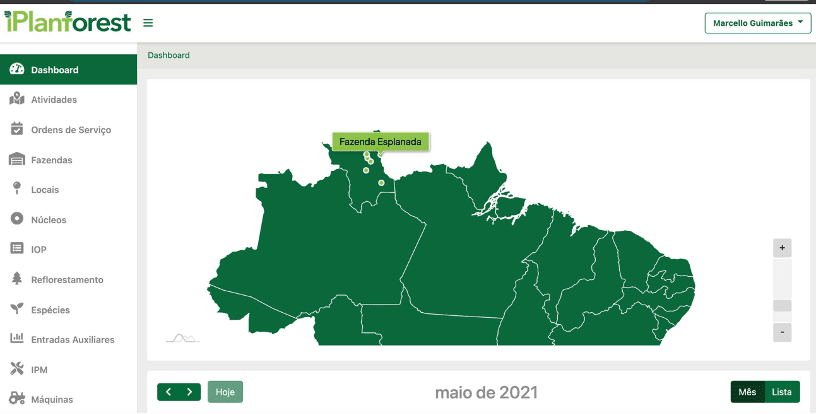

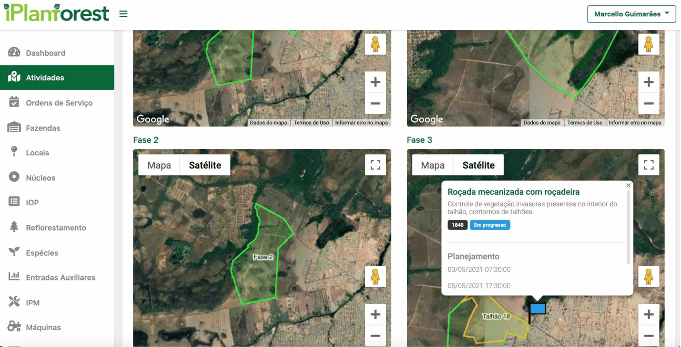

The graphic representation below shows our monitoring model in operation, merely as an example:

Management system iPlantForest.

INTEGRAL MACHINE MANAGEMENT / ERP – Enterprise Resource Planning

With the integration of Forest.Bot (Patent Pending) to the ERP system developed by iPlantForest (a consortium that makes up the AutoAgroMachines business group), we have achieved more significant control of all activities, ranging from planting to forest management in real-time (depending on the availability of the internet on site). The machine is ready for operation with a map of the planting that will be carried out, spacing between rows, and spacing between seedlings. It records all information about the planting of each seedling in the database.

As part of this functionality package, the customer receives access to the platform that controls the planting maps to manage forest management services.

The gain in productivity and the increase in security in the planting process is the differential of our embedded technology, allowing the customer to manage their agricultural projects using the services available after planting that can be controlled and managed based on the GPS position of each seedling.

FBLink

The machines Forest.Bot (Patent Pending) is all prepared to receive FBLink technology (Forest.BOT Link). By default, the machines Forest.Bot (Patent Pending) receives the installation of FBLink even in its standard version. This tool allows remote monitoring of the machine through your computer or tablet.

Our constant evolution in technological solutions embedded in a consolidated engineering project allowed AutoAgroMachines to make available in our exclusive Forest.Bot (Patent Pending) version 9.0 has the following functions:

OPTIMIZATION OF MACHINE DATA

Operational efficiency.

- Connection to utility service packages.

REMOTE SERVICES

- Remote software package upgrade.

- Remote diagnostics.

MACHINE AVAILABILITY

- Preventive maintenance.

- Maintenance plans recommended by Forest.Bot (Patent Pending).

- Customized plans – calendar/hours.

- Management of alerts and error codes.

- Monitoring of machine parameters.

GEOREFERENCED PLANTING MAP

The consequence of adopting an activity management model using exclusive software developed for the Forest.Bot (Patent Pending) version 9.0 allows all machine activities to be recorded in the Forest.Bot (Patent Pending) is automatically transferred to the cloud and/or the company’s system, loading the information as soon as the machine identifies an authorized internet connection. The quality control of planting takes place through the system, checking each of the photos of each planted seedling. The system identifies in the image any failure in the planting, either in the sinking of the collar, exposure of the substrate, when there are problems in the inclination of the seedling, as in the example images below collated:

Geoprocessed plantings iPlantForest.

Final considerations:

AutoAgroMachinesis proud to be a Brazilian company. It started its research and construction of the prototypes in the Legal Amazon, creating technological solutions and mechanical engineering projects to contribute to the environment in a sustainable vision of all stages of agribusiness.

Identify the applicability potential of our Forest.Bot (Patent Pending) version 9.0 in agricultural operations only confirms what was already presented as reality in the market, our customers’ vision of the future, which is found in the innovation built by AutoAgroMachines, the ideal partner.

The future belongs to those who make innovation their goal and Forest.Bot (Patent Pending) is prepared to meet the functionality expectations of our solutions.